{Handling the demanding requirements in subzero processes relies on tailored valve solution. The company’s glacial 3-way ball assembly remedies are constructed to provide consistent productivity even at ice-cold temperatures, typically below -150°C. These mechanisms offer extraordinary conveyance control in chilled materials such as nitrogen, oxygen, and argon, frequently used in branches like LNG, experimental equipment, and medical facilities. Our group specialize in resilient construction, including reduced-friction closure materials and careful shaping, to certify tight-fitting running. Consider the pros of refining your arctic system with our innovative 3-way spherical mechanism solutions.

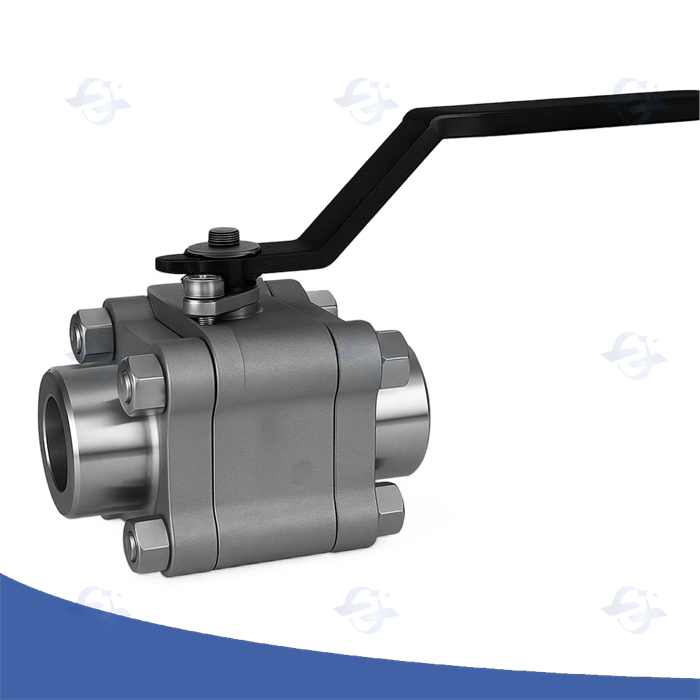

Top-Quality Double Block and Bleed Ball Valve Assemblies

About stringent deployments, particularly where escaping is disallowed, advanced double block and bleed orbital valves offer unequalled safety. This novel design incorporates two individual gate valve seals, besides a bleed aperture, allowing for confirmation of the full shut-off and recognition of any possible oozing. Generally employed in petroleum extraction, synthesis conversion, and low-temperature atmospheres, these units significantly elevate facility dependability and reduce the exposure of environmental impact.

Three-Directional Glacial Orbital Tap Formation

An formulation of three-way frosty circular tap presents a special engineering problem. These instruments are regularly employed in fundamental industrial deployments where extreme chills must be sustained. Key points include element adoption, notably regarding vulnerability at low climatic states, and the need for snug shutting to inhibit seepage of cold gases. Refined study systems and rigorous manufacturing processes are required to ensure reliable execution and lifespan under such tough functional states.

Glacial Regulator Operation in Technical Applications

That demanding specifications of glacial operations, such as liquefied natural combustible handling and frozen nitrogen storage, necessitate dependable regulator designs. Integral block release instruments provide a particularly robust and effective approach to achieving zero-leak closure while facilitating frequent maintenance. Their design includes a primary mechanism with a small outlet bore, allowing administered pressure release during sealing and start-up. This inherent feature minimizes unwanted substance entrapment, thereby ensuring unrivaled safety and productivity even under the most rigorous performing conditions. Furthermore, the facility to oversight purge movement provides valuable testing details for procedure augmentation.

Confirming 3-Way Ball Valve Tightness in Demanding High-Pressure Situations

Ensuring solid closure performance with 3-way sphere valves becomes particularly critical when operating within great pressure environments. The design is required to account for significant weights and potential seepage pathways. Specialized materials, often including advanced metals like hardy steel or exotic alloys, are vital to cope with the extreme conditions. Furthermore, intricate fitting geometries and exact formation processes are essential to minimize compression and guarantee a airtight union even under fluctuating load cycles. Regular audit and preemptive maintenance programs are as well vital for continuity and prolonged operational performance.

Glacial Ball Valve Leakage Prevention Strategies

Mitigating "leakage" from cryogenic "orbital valves" demands a multifaceted "procedure". Initial "engineering" considerations are paramount; material "adoption" must account for extreme "coldness" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "composition", meticulous "production" processes – including stringent weld "evaluations" and non-destructive "assessment" – are vital to ensure structural integrity and eliminate voids that could become "leakage paths". A "critical" component is proper "installation"; thermal "decrease" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "care" – including periodic "scrutiny" for signs of wear and "mending" of any identified issues – is indispensable for maintaining a reliable, leak-tight "barrier”. Ultimately, a robust "scheme" incorporating these elements is necessary to ensure the safe and efficient "functionality" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "perils", and costly "halt”.

Double-Set Shutoff and Exhaust Mechanism Examination Methods

For ensuring the integrity and safety of critical piping networks, rigorous paired clamp and vent component check methods are essential. These tests, often mandated by regulatory bodies and industry best principles, typically involve simulating simultaneous closure of two isolation apparatuses while simultaneously ensuring the bleed mechanism remains functional and correctly discharges any trapped material. A common mode is to utilize a pressure analysis where the system is pressurized to its maximum working pressure, and the seepage rate around the closed mechanisms is meticulously tracked. The drain apparatus's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of examination results, including any outliers observed, is critical for maintaining a reliable operation.

Grasping Whole Block Drain Mechanism Performance

With the purpose to accurately oversee load structures, a detailed grasp of integral block bleed unit work is totally vital. These particular components largely operate to securely let out extra pressure from a framework during defined utilized steps. A typical arrangement involves a fitted chamber coupled to the main load source, authorizing the led release as soon as vital. The intrinsic format lowers the danger of beyond-limit pressure, protecting both the gear and the encompassing habitat. Regular supervision and upkeep are important to verify maximal function.

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Selecting a suitable 3-tri-ball instrument for cryogenic operations demands careful evaluation of several critical aspects. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present exclusive challenges. Material preference is paramount; only materials with proven matching and ductility at these temperatures, such as durable steel grades like 304L or 316L, or specialized alloyed alloys, should be reviewed. Furthermore, the device's sealing capability is vital to prevent discharges, requiring unique stem sealing structures and low-temperature lubricants. Finally, pressure scales and actuation approaches, taking into account potential pressure spikes, must be rigorously matched to the system's demands. Neglecting these elements can lead to disastrous failure and safety risks.

Glacial Spherical Valve Component Suitability Catalog

Selecting the appropriate element for cryogenic ball valves is paramount, given the harsh temperatures involved. This compendium highlights common materials and their response when exposed to cryogenic fluids such as compound nitrogen, liquid helium, and oxygen. Stainless steels, particularly varieties 304 and 316, often demonstrate adequate resilience and deterioration resistance, though martensitic alloys require careful consideration regarding weakness. Aluminum alloys can be suitable for certain applications, however, their elasticity and safeguard to specific chemicals needs careful evaluation. Copper alloys, while offering some benefits, may exhibit lessened functionality at these reduced temperatures. Consultation with providers and comprehensive analysis is essential to ensure continuity and dependability in cryogenic applications.

Increasing Double Seal and Release Installation Efficiency

Realizing optimal performance in double block and bleed installations hinges on a multifaceted approach. Careful review of mechanism selection is critical, with a focus on compound compatibility and force ranking. Regular review of exhaust conduits for blockage is mandatory, often demanding the use of exclusive analysis machines. Furthermore, protocol modernization—including checking of transit rates and pressure disparity—can noticeably boost overall arrangement solidity and protection. Finally, alignment to creator guidelines and the enforcement of a comprehensive preservation routine are unavoidable for long-term performance and endurance.

Integral Block Bleed Valves

Integral Block Bleed Valves