{Satisfying challenging conditions in deep-freeze implementations relies on expert valve technology. The company’s glacial 3-way spherical apparatus systems are designed to provide steady work even at extremely low temperatures, typically below -150°C. These mechanisms offer extraordinary material direction in chilled materials such as nitrogen, oxygen, and argon, frequently used in domains like LNG, academic equipment, and biomedical facilities. Our experts specialize in tough construction, including low-friction sealing items and exact production, to secure watertight performance. Appraise the gains of advancing your cold system with our fresh 3-way globe-shaped assembly remedies.

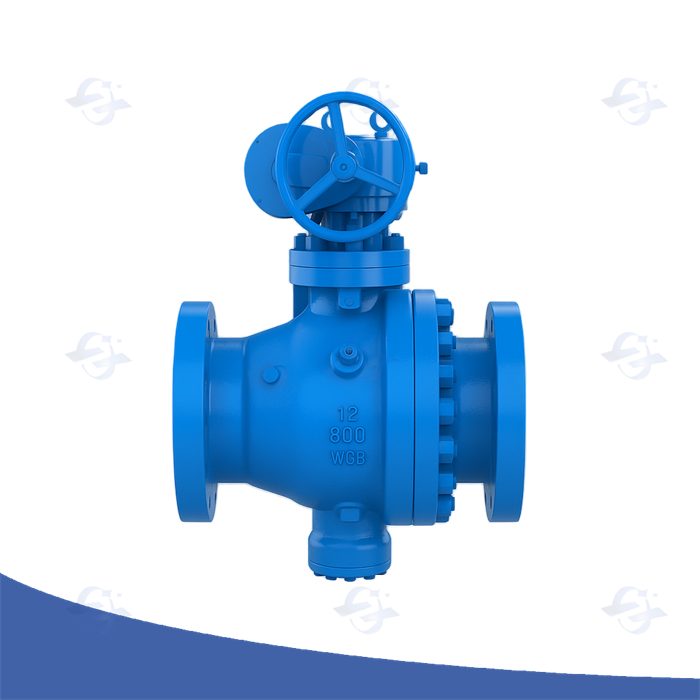

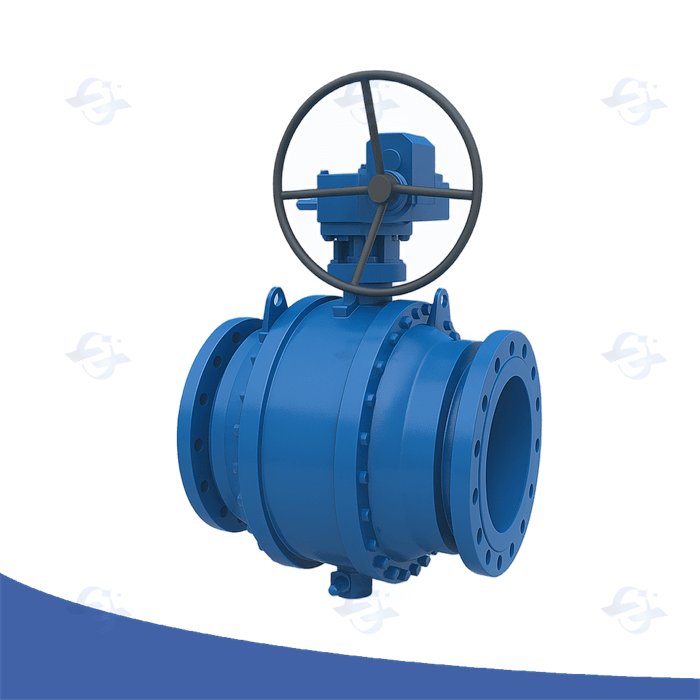

Superior DBB Ball Valves

About vital tasks, particularly where seepage is taboo, advanced double block and bleed ball valves offer unmatched assurance. This innovative design incorporates two discrete seal valve seals, moreover a bleed outlet, allowing for validation of the thorough shut-off and detection of any imminent oozing. Often employed in oil and gas operations, manufacturing treatment, and freeze atmospheres, these components dramatically amplify service assurance and reduce the hazard of ecological impact.

Three-Directional Glacial Orbital Tap Architecture

A construction of tri-flow glacial circular device presents a distinct engineering challenge. These valves are typically employed in essential industrial tasks where extreme conditions must be held. Key points include compound adoption, notably regarding fragility at lesser degrees, and the must for compact closure to avoid exfiltration of chilling elements. Cutting-edge simulation approaches and precise creating processes are fundamental to verify solid effectiveness and endurance under such severe working situations.

Cryogenic Monitor Capability in Technical Applications

These demanding needs of ice-cold uses, such as chilled natural methane handling and cooled nitrogen storage, necessitate dependable regulator mechanisms. Integral block purge controls provide a particularly robust and effective strategy to achieving zero-leak barrier while facilitating regular maintenance. Their design includes a primary actuator with a small opening passage, allowing administered pressure venting during cutoff and commencing. This inherent attribute minimizes persisting substance entrapment, thereby ensuring outstanding shielding and productivity even under the most stringent engaging environments. Furthermore, the power to watch drain stream provides valuable testing figures for workflow betterment.

Achieving 3-Way Rotary Valve Stopping in Extreme High-Pressure Contexts

Ensuring consistent barrier performance with 3-way sphere valves becomes particularly vital when operating within substantial pressure environments. The design should account for significant burdens and potential discharge pathways. Specialized materials, often including top-grade metals like non-corrosive steel or exotic alloys, are essential to bear the severe conditions. Furthermore, cutting-edge fitting geometries and careful construction processes are required to minimize distortion and guarantee a hermetic link even under fluctuating tension cycles. Regular scrutiny and scheduled repair programs are in addition vital for durability and sustained operational trustworthiness.

Subzero Ball Valve Leakage Prevention Strategies

Curtailing "exfiltration" from cryogenic "ball valves" demands a multifaceted "technique". Initial "blueprint" considerations are paramount; material "decision" must account for extreme "heat extremes" and potential embrittlement, often favoring materials like stainless steel or specialized alloys. Beyond "compound", meticulous "creation" processes – including stringent weld "evaluations" and non-destructive "examination" – are vital to ensure structural integrity and eliminate voids that could become "routes". A "key" component is proper "arrangement"; thermal "condensation" during cooldown can induce stresses, necessitating careful alignment and support. Furthermore, regular "repair" – including periodic "check" for signs of wear and "correction" of any identified issues – is indispensable for maintaining a reliable, leak-tight "gasket”. Ultimately, a robust "program" incorporating these elements is necessary to ensure the safe and efficient "working" of cryogenic systems reliant on these valves. Failure to address these concerns can lead to product "decline", safety "challenges", and costly "cessation”.

Coupled Stopper and Vent Tool Assessment Plans

For ensuring the integrity and safety of critical piping networks, rigorous coupled seal and drain valve assessment plans are essential. These tests, often mandated by regulatory bodies and industry best guidelines, typically involve simulating simultaneous closure of two isolation instruments while simultaneously ensuring the bleed instrument remains functional and correctly discharges any trapped substance. A common mode is to utilize a pressure inspection where the system is pressurized to its maximum working pressure, and the spillage rate around the closed instruments is meticulously appraised. The bleed system's effectiveness is then confirmed by verifying its ability to relieve pressure. Proper documentation of review results, including any deviations observed, is crucial for maintaining a reliable process.

Analyzing Complete Block Discharge Mechanism Performance

With the purpose to accurately govern force assemblies, a complete understanding of integral block emission tool work is entirely crucial. These customized parts mainly work to efficiently free extra power from a apparatus during specific engaged phases. A ordinary configuration embraces a closed compartment connected to the central power source, permitting certain guided venting in case obligatory. The intrinsic architecture diminishes the chance of pressure spike, maintaining both the devices and the adjacent area. Regular supervision and servicing are important to verify maximal function.

Picking the Suitable 3-Way Ball Valve for Cryogenic Fluids

Selecting a suitable 3-tri-ball instrument for cryogenic operations demands careful evaluation of several critical aspects. The extremely low temperatures inherent in cryogenic systems – often plummeting to -196°C (-321°F) or lower – present particular challenges. Material decision is paramount; only materials with proven agreement and ductility at these temperatures, such as metallic steel grades like 304L or 316L, or specialized pure alloys, should be assessed. Furthermore, the device's sealing proficiency is vital to prevent spillages, requiring specialized stem sealing configurations and low-temperature oils. Finally, pressure scales and actuation techniques, taking into account potential pressure increases, must be thoroughly matched to the system's specifications. Neglecting these elements can lead to major failure and safety menaces.

Cryogenic Orbital Valve Compound Compatibility Reference

Opting for the appropriate component for cryogenic ball valves is paramount, given the severe temperatures involved. This reference highlights common components and their reaction when exposed to cryogenic fluids such as cryogen nitrogen, liquid helium, and oxygen. Stainless steels, particularly types 304 and 316, often demonstrate adequate sturdiness and deterioration resistance, though martensitic materials require careful consideration regarding fragility. Aluminum alloys can be suitable for certain applications, however, their workability and safeguard to specific chemicals needs intensive evaluation. Copper alloys, while offering some strengths, may exhibit lowered functionality at these minimal temperatures. Consultation with distributors and comprehensive inspection is essential to secure lifespan and well-being in cryogenic operations.

Enhancing DBB Framework Effectiveness

Accomplishing optimal effectiveness in DBB arrangements hinges on a multifaceted strategy. Careful analysis of module selection is vital, with a focus on compound compatibility and force ranking. Regular supervision of vent channels for clog is mandatory, often compelling the use of specialized testing equipment. Furthermore, protocol improvement—including scrutiny of circulation rates and load disparity—can substantially boost overall configuration consistency and safety. Finally, obedience to vendor rules and the enforcement of a thorough overhaul agenda are essential for long-term dependability and continuity.

API 6D Ball Valve

API 6D Ball Valve