Within the sphere of manufacturing procedures, securing the entirety and output of lines is necessary. Gathering of fouling within ducts can markedly restrict flow velocity, lessen commodity level, and augments operational expenditures. To deal with these complications, tube cleansing systems have appeared as remarkably potent answers for effective channel cleaning. A apparatus, commonly a round instrument, is displaced through the channel, productively eliminating deposits and accomplishing highest effectiveness

Tube sanitation methods extend diverse strengths. They are resourceful, prepared for purifying pipelines of mixed widths and content. Furthermore, they are capable, executing the function in a fairly fast duration. By slashing downtime and upgrading pipeline capacity, pipeline cleaning systems advance cost reductions and enhanced operational work

Hygiene Pigging Techniques:

Keeping pipeline hygiene is critical for affirming goods protection and value of shipped products. Sanitary pigging methods provide a durable way to achieve this intention. Pigs, particular apparatus, are put in into pipelines to sanitize by taking out residues and pollutants

- Multiple categories of sanitary pigs are found, each created for particular cleaning duties.

- These pigs are developed from elements that follow stringent safe standards.

- Systematic sanitary pigging tasks help stopping product tainting, prolong pipeline stability, and strengthen complete productivity.

Sophisticated Pigging Platforms for Optimal Output

pigging systemAmong the landscape of conduit servicing, innovative pigging mechanisms have become a key device for providing prime operation and safety. These pioneering systems exploit breakthrough schematics and functions to successfully scrub, analyze, and secure lines from impairment. From intelligent pigs fitted with instantaneous observation tools to designed pigging apparatus developed for careful tasks, growth in this branch is constantly pushing boundaries. By embracing these technologies, users can significantly enhance pipeline integrity, minimize downtime, and maximize operational productivity.

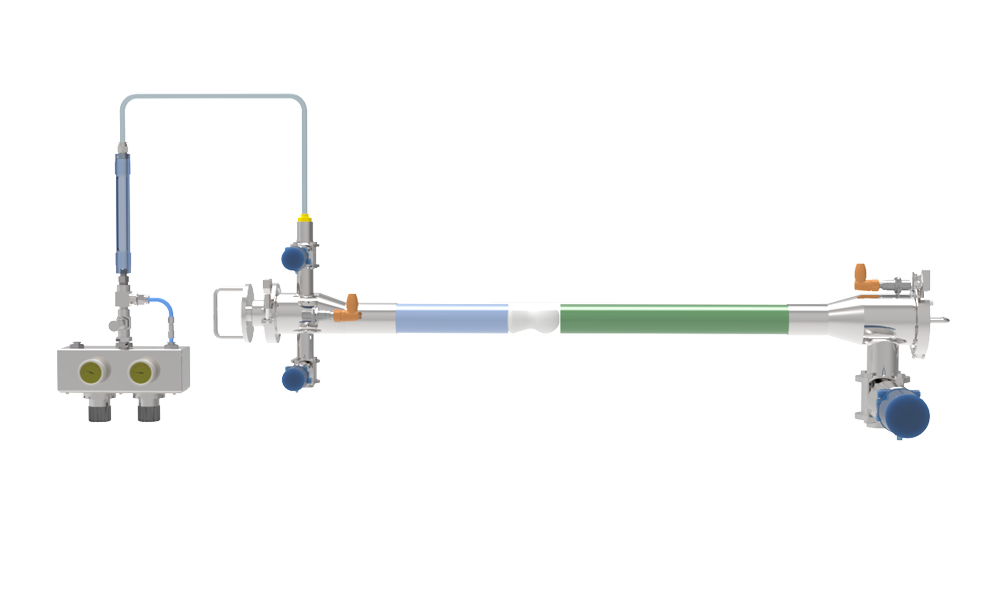

Comprehensive Pigging System Design and Assembly

Each broad-based pigging system incorporates a pivotal technique for pipeline repair. This mechanism entails the placement of tailored tools called pigs, which navigate through tubes to disinfect, survey, and maintain their integrity. The configuration puts weight on components such as tubing thickness, fabric, pig style, and operational prerequisites. A thoughtful system guarantees robust pigging functions while decreasing downtime and potential injuries. Installation methods call for careful arrangement, skilled engineers, and strict adherence to safety regulations to ensure a secure and favorable conclusion

Industrial Pigging Solutions for Extensive Uses

Engineering pigging products are key components utilized across a ample variety of industries. These mechanisms encourage safe and competent cleansing, assessment, and preservation of pipes and other pipe-like constructions. Pigging includes deploying engineered tools known as pigs through pipes to undertake various responsibilities. Typical types of industrial pigging implements incorporate cleaning pigs, inspection pigs, and transfer pigs. Cleaning pigs are built to displace debris, build-up, and defilements from pipelines. Inspection pigs are supplied with measuring tools that acquire information about the health of pipe surfaces. Transport pigs are deployed to hauler gases through pipelines. The use of industrial pigging products furnishes numerous benefits, such as reduced downtime, augmented pipeline integrity, and bolstered operational capability. These devices are universally installed in industries such as oil and gas, water treatment, chemical production, and food manufacturing.Extensive Pipeline Pigging Manual

Pipeline pigging is an critical operation used within the oil and gas arena to inspect pipelines. This key methodology consists of deploying tailored contraptions, named pigs, into the pipeline. Pigs are constructed to navigate the coverage of the pipeline, fulfilling various functions.

Several classes of pigs are at one's fingertips, each built for a distinct purpose. Common functions of pipeline pigging embrace checking for defects, cleansing, and applying coatings.

- Advantages of Pipeline Pigging

- Influences on Operational Efficiency

- Groups of Pipeline Pigs

Dependable Sanitation by means of Pigging Methods

Pigging arrangements contribute a stable answer for promoting sanitation inside pipelines. These systems utilize custom-made devices that travel through the tube system, successfully removing deposits. The method is especially beneficial for sectors that demand rigorous hygiene criteria. Pigging approaches supply a cost-saving and fast approach for washing tubes, curbing the chance of cross-contamination.

Choosing Pigging Equipment for Exclusive Prerequisites

Pigging machinery performs a vital role in efficient pipeline functioning. When appointing pigging instruments, it is important to consider the unique needs of your assignment. This embraces analyzing factors such as pipeline breadth, flow movement, product form, and maintenance requirements.

Countless pigging choices are available, each developed for distinct missions. As an example, some pigs are meant for reviewing, while others are deployed for extracting debris or distributing product parcels.

Additionally, pigging instruments units should be suitable with the delivered liquid.

It is always beneficial to collaborate with a engineer in pigging equipment to ensure that you go for the most suitable instrument for your individual wants.

Flow Line Sanitation Systems - A Value-Adding Approach

Channel purging solutions deliver a extensive variety of assets for domains working with pipes. By skillfully purging and surveying tube insides, pigging systems raise operational capability and decrease maintenance outgoings.

A principal virtue of pigging systems is their ability to eradicate build-up such as layering, debris, and oxidation products. This routine maintenance secures easy pipeline circulation and obviates costly downtime.

As well, pigging systems can be used to check the soundness of pipelines, identifying imminent complications before they intensify into significant obstacles. This tactical approach supports to enhance survival of pipelines and shrink overall maintenance expenditures.

Securing Hygiene in Pigging Tasks

Sow rearing practices substantially lean on appropriate hygiene guidelines to inhibit the spread of pathogens. Observing rigorous hygiene procedures facilitates a vital environment for pigs, that contributes to superior health outcomes and yield.

Frequent cleaning and disinfection of sites is necessary to block the spread of harmful bacteria. Adequate waste management in addition acts a significant part in ensuring hygiene.

Moreover, {workers