On occasions involved profiled pipe engineering and fabrication, linking with certified authorities is paramount. These knowledgeable fin tube generation experts possess a broad comprehension of heat distribution principles, matter traits, and the modern practices for creating reliable heat exchangers. They deal with everything from design inception and trial construction to mass output and thorough review. Adopting the right finned tube fabrication master can substantially improve the efficiency and service life of your system.

State-of-the-art Extended Pipes

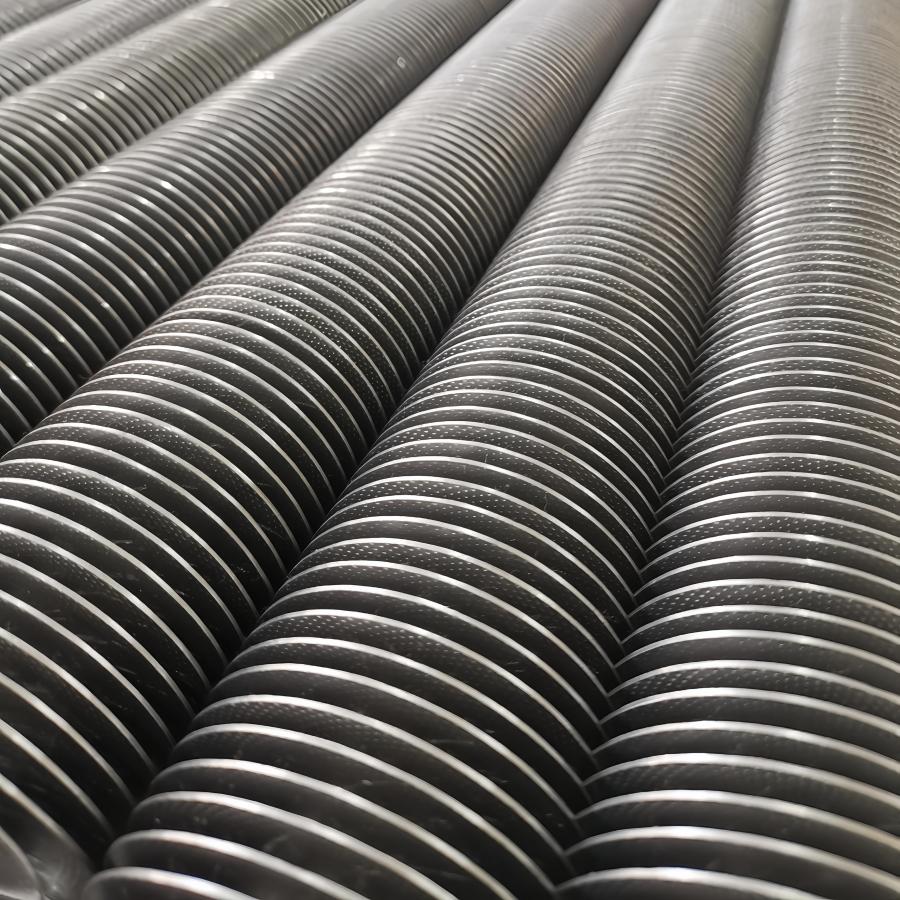

Leading-edge manufacturing uses frequently demand particularly efficient temperature transfer, and maximized finned systems are vital to achieving this. These fragments contain carefully designed projection geometries, commonly executing sophisticated patterns to expand the area available for warmth conduction. Building processes may incorporate molding, joined by meticulous fin shaping and intermittently a unique surface treatment to supplementarily elevate functionality. Going for the right finned pipe pattern is influenced on the certain utilization parameters, namely material parameters, thermal states, and pressure magnitudes.

Specialized Finned Copper-alloy Line Solutions

Confronting challenging thermodynamic management necessities? Our expert team develops purpose-built copper pipeline systems precisely designed for your application. We harness advanced creation techniques and specific calculations to enhance temperature spread efficiency. Whether you're in the automotive sector, or need enhanced cooling intended for a sensitive apparatus, our finned copper conduits can furnish strengthened operation. We appraise factors such as media transit rates, proximal thermal states, and structural constraints designed for design a truly singular and effective answer.

Advisors in Grooved Aluminum Tube Services

For decades, we've been dedicated to providing unparalleled expertise in ribbed aluminum pipe design, assembly, and installation. As leading technicians, we offer a comprehensive array of services, catering to a far-reaching spectrum of industries, including thermal management, electricity generation, and chemical processing. Our group of experienced engineers has a deep understanding of heat movement principles and constituent science, ensuring that every job we undertake delivers optimal effectiveness and endurance. We believe ourselves on delivering tailored options that precisely conform to our clients’ unique requests. Whether you require thermal exchanger repair, renewal, or a full system blueprint, our pledge to premium quality remains unwavering. Get in touch us today to explore your definite complications.

Augmented Tube Engineering and Counseling Presentations

Improving thermal flow efficiency is paramount in countless domains, and that's where specialized enhanced tube configuration and guidance packages truly shine. We provide comprehensive options encompassing everything from initial design to full-scale implementation. Our personnel of experienced specialists leverage advanced digitalization techniques and field best methods to assemble personalized finned tube units for a wide array of complex environments. Whether you're seeking to enhance output, lessen resource costs, or address specific system issues, our upgraded tube expertise ensures maximum results. We also offer periodic support aid to maintain ongoing operational integrity.

Progressive Precision Finned Tube Assembly

The conditions of modern heat conduction systems are prompting a transition towards highly focused finned tube practices. Traditionally, uncomplicated fin configurations were permissible, but now applications in semiconductors and process processing necessitate severely tight tolerances and elaborate geometries. This involves detailed fabricating of fins directly onto the tube form, often utilizing innovative cold fabrication equipment to gain the desired fin elevation, separation, and structure. Moreover, the fabric selection plays a critical role, with unique blends frequently implemented to maximize thermal output while maintaining formative robustness. Class monitoring systems are also important to preserve stable ribbed tube standard.

Profiled Copper Pipe for Heat Exchangers

Contemporary heat conduction systems frequently use finned copper channel as a crucial factor in heat exchangers. The insertion of fins, traditionally made from aluminum, significantly aluminium finned tubes increases the surface surface available for heat transfer, leading to a improved efficient heat conversion. These improved copper pipes are commonly found in applications ranging from commercial processes, such as chilling machinery, to home HVAC systems. The outstanding thermal heat flow of copper, matched with the augmented surface zone provided by the fins, causes in a significantly effective method for controlling heat. Different fin patterns, including flat and coiled, offer varying degrees of performance optimization depending on the specific application’s standards.

Contemporary heat conduction systems frequently use finned copper channel as a crucial factor in heat exchangers. The insertion of fins, traditionally made from aluminum, significantly aluminium finned tubes increases the surface surface available for heat transfer, leading to a improved efficient heat conversion. These improved copper pipes are commonly found in applications ranging from commercial processes, such as chilling machinery, to home HVAC systems. The outstanding thermal heat flow of copper, matched with the augmented surface zone provided by the fins, causes in a significantly effective method for controlling heat. Different fin patterns, including flat and coiled, offer varying degrees of performance optimization depending on the specific application’s standards.Aluminum Finned Tubes: Lightweight & Efficient

Aluminum augmented tubes offer a compelling combination of compact construction and remarkable capability, making them ideal for a varied range of manufacturing heat transfer systems. Their unique structure—featuring aluminum fins attached to the tube shell—significantly raises the heat exchange strength without adding substantial weight. This translates to minimized energy expenditures and improved overall workflow soundness. Consequently, these tubes are frequently picked in HVAC equipment, refrigeration, and other heat transferring processes where minimizing pressure and maximizing energy transfer are paramount points.

Finned Tube Compound Options: Copper-based & Aluminium Alloy

Whenever picking finned tube compound, engineers frequently examine copper and aluminum. Copper offers exceptional degradation withstand and superior temperature conductivity, making it optimum for applications where high-performance heat transfer is paramount, such as in climate control systems. However, copper's raised valuation and probable for galvanic corrosion with other minerals can be limiting factors. Conversely, aluminum provides a significantly lower rate and benefits from a lower density, which is advantageous in weight-sensitive designs. While aluminum's thermal conductivity is lower than copper's, it remains adequate for many applications, and surface treatments can often improve its performance. Ultimately, the best material selection hinges on a thorough analysis of the specific operating conditions, budget constraints, and required performance characteristics.

Boosting Heat Conduction with Finned Hollow Bodies

The productivity of heat exchangers frequently hinges on the design and execution of finned pipes. These structures significantly raise the surface area available for heat dissipation, allowing for a much greater discharge of heat compared to simple, unfinned tubing. The promotion process involves a complex interplay of factors, including fin profile – such as fin magnitude, spacing, and breadth – as well as the constituent of both the fins and the basic tubing themselves. Careful consideration of the liquid flow characteristics, whether it's air or a mass, is also paramount to ensure that the heat dispelling isn’t restricted by boundary layer effects or uneven dissemination of the working substance. Ultimately, a well-designed finned section array delivers a considerable improvement in overall thermal functionality within a given space.

Tough Finned Tube Setups for Industrial Applications

Handling the conditions of demanding manufacturing environments necessitates strong heat flow apparatus. Our finned tube lines are engineered for exceptional performance, providing regular heat diffusion in a range of applications, from petroleum processing to air-conditioning control. Constructed from finest materials and featuring advanced erosion durability techniques, these modules minimize maintenance downtime and maximize operational efficiency. The tailored fin arrangement promotes increased heat distribution, even under challenging operating conditions.