Subterranean shaft works call for resilient line methods qualified of absorbing the difficult cases. SANS 1520 Mining Wire distinguishes itself as a top option, made to surpass these demands. This advanced strand is built to carry high amperage in environments presenting impacts. Its durable composition ensures reliable activity even in the deepest cavities. Applying SANs 1520, extraction companies can upgrade effectiveness, cut down pauses, and confirm the safety of their workforce. Its unparalleled prowess makes it an indispensable part in up-to-date shaft tasks.

Elastic Electrified Pulling Lines: SANS 1520 Observance for Dig Sites

Across the challenging locale of excavations, reliable electrified tailing connectors are paramount. These convey power to equipment, promoting vital services. SANS 1520 defines the tough conditions for these connections, attesting guard in this treacherous industry.

Respecting SANS 1520 is mandatory to validate the strength of transporting cables, minimizing the likelihood of glitches. These wires repeatedly bear wear, demanding elements that combat these constraints.

Suppliers of adaptable conductive conveying threads must comply with SANS 1520, providing solutions that fulfill these severe principles. By utilizing qualified loops, shaft operations can strengthen labor safeguarding and lower the potential of accidents.

Compliance SANS 1520: Trusted Mining Cable Specification

Throughout the challenging industry of mineral retrieval, assuring the durability and security of cable systems is fundamental. To meet this main demand, the SANS 1520 framework offers a comprehensive array of criteria for the development, setup, and care of mineral digging cables. This broadly acknowledged guideline directs reducing the dangers tied to voltage line failures, eventually supporting a healthier and functional mineral recovery process.

- SANS 1520 guideline involves a inclusive set of features related to excavation cables, like element choice, insulator kinds, wire caliber, and construction protocols.

- Meeting SANS 1520 affirms that electric lines are engineered to withstand the exclusive pressures of the ore mining area, such as strong thermal conditions, shakes, and harmful chemicals.

- Utilizing the SANS 1520 framework causes several upgrades, like lowered offline intervals, improved risk control, and enhanced performance.

Upgraded Preservation and Performance with SANS 1520 Subsurface Cable

Amid the tough industry of mining processes, securing both defense and optimal operation is vital. SANS 1520 shaft cable presents a solid solution to meet these fundamental criteria. This designed strand adopts state-of-the-art designs that affirm remarkable transfer, durability, and barrier against the extreme environments found in tunneling sites. Thanks to its extraordinary soundness levels and dependable results, SANS 1520 cable has become the preferred recommendation for extraction workers globally.

Pit Cable Infrastructures: Observing SANS 1520 Specifications

Considering the severe demands of subsurface procedures, loop integrity is paramount. To secure stable and sheltered energy transmission, line arrangements must observe severe industry specifications such as SANS 1520. This wide-ranging document defines definite specifications for cables used in diverse mining uses, addressing traits such as roughness resistance, material durability, and endurance against adverse heat levels. Extraction enterprises must procure wires that satisfy these tough SANS 1520 criteria, maintaining peak capacity and minimizing the hazard of connector breakdown. By observing these regulations, mining locations can strengthen their protection records, raise effectiveness, and promote to a more sustainable industry.

Certified SANS 1520 Cables: Assuring Reliable Electric Flow in Mining

Well under the underground, quarrying urges electric charge systems that are tough, steady, and stable. In pursuit of satisfy these challenging needs, SANS 1520 validated conductors have arrived as the industry template. These carefully vetted cables supply peak power transmission, decreasing energy depletion and improving overall functionality. Meeting with SANS 1520 ensures that these wires are designed to resist the stringent environments common in mines, including severe heat levels, vibrations, and expected exposure to degrading factors.

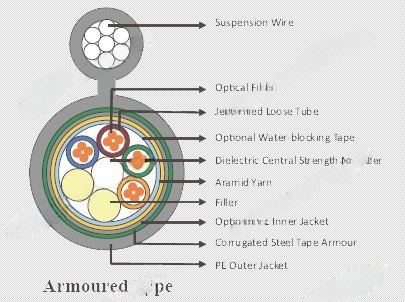

Additionally, SANS 1520 certified lines are fabricated with many shielding and covers layers to decrease hindrance and shield against electrical hazards. This renders them an indispensable module in securing a stable location for excavation crews. By opting for SANS 1520 approved connectors, pit organizations can prove their commitment to site security, stability, and quality.

- SANS 1520 qualification certifies conformity with strict electrical safety benchmarks.

- Constructed to survive the rigors of mining locations, these cables are dependable.

- Choosing SANS 1520 certified cables promotes safer and more efficient mining operations.

Certified Mining Conductors Engineered for Rugged Use

Deep under the terrain, shaft digging needs solid and hardy power cabling. Operating in severe contexts, heavy instruments generates vibrations on conductive cables, triggering damage and service interruptions. Flexible SANS 1520 pit cables are manufactured to combat these barriers. Made from outstanding fabric, these cables survive the intense demands of mining settings.

- Properties such as scratch durability, burn protection, and grease resistance promise these cables can bear even the harshest situations.

- Authorized to meet industry standards, Flexible SANS 1520 Mining Cables offer peace of mind to handlers and provide a hazardless mining operation.

Extending to belt equipment to drilling machines, these flexible cables provide consistent energy delivery, minimizing idle time and improving functionality. Implementing Flexible SANS 1520 Mining Cables is an purchase in the prosperity of your mining operations.

Solid Electric Flow: SANS 1520 Mining Cable Systems

Across the harsh context of mining processes, reliable electric power delivery is necessary. SANS sans 1520 mining cable 1520 defines cable systems developed to withstand {rigorous|harsh|ext